We Don’t Just Follow Safety Standards—We Help Set Them.

We are proud to be the first manufacturer certified by UL for chainsaw protective garments in the US. Being a leader in safety apparel doesn’t allow us room to relax. Our team has played an integral part in refining the standard as fabrics and technology have changed over the past 30 years. We will continue to lead this effort to ensure that the high level of safety protection doesn’t change, even if technology does.

Safety Fabrics

Technical

Size Chart

Wash and Care

Innovative Fabrics, Unyielding Protection

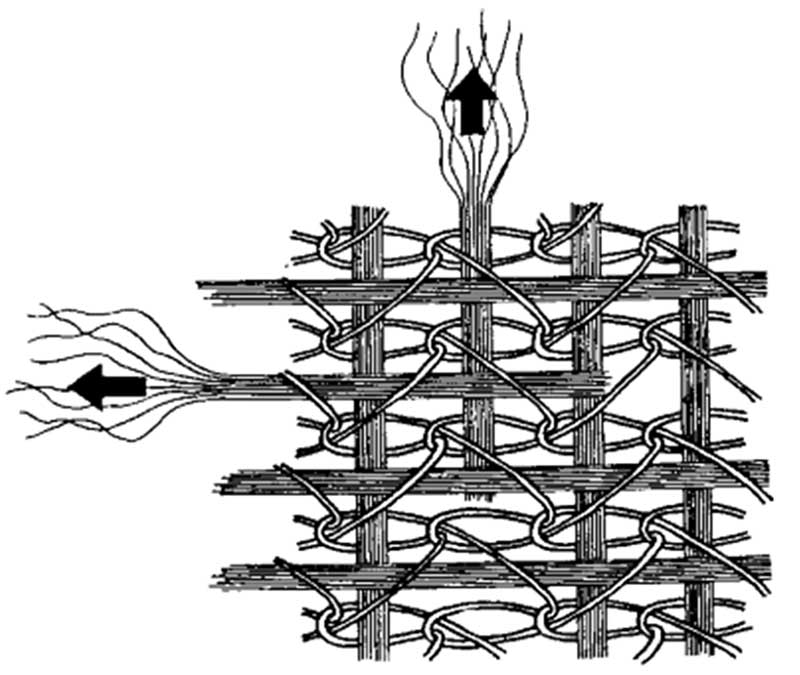

At the heart of all of our chainsaw protective apparel is Engtex Avertic® Pro+ fabric. Since the early 1980’s, Engtex has been the leader in textiles for protection and cut prevention. The Avertic product line is known and used around the world for chainsaw protective products, meeting a multitude of international standards. Component fabrics are chosen for their properties as they relate to the product use, including oil and water resistance, stretch, and abrasion resistance.

Technical

US Leg Protection Standard

ASTM F1897 - North American Standard for chainsaw safety leg apparel. This standard identifies all attributes a compliant chainsaw leg garment must have. It indicates exactly how the garment must be labeled and all warnings that must be present.

ASTM F1414 - Test method for chainsaw protective leg apparel. This test method delineates the methodology, instruments, equipment, and materials to complete the testing procedure. Each product must be tested annually by an independent testing organization. Underwriters Laboratory is the premier testing facility in the US and maintains the files for all compliant products in the US.

Avertic® Pro+ Fabric Specifications

| Avertic® Pro+ | Avertic® Pro+ Lite | |

| Layer Weight g/m² | 160 | 130 |

| Minimum Layers | 6 | 6 |

| Total Weight g/m² | 960 | 780 |

| Material Composition | 100% Polyester | 79% Polyester 21% Polyethylene |

US Boot Standard

ASTM F2413

M – Protects against metatarsal impact

I – Protects against toe impact

C – Protects against compression

EH – Protects against open circuits up to 600 volts in dry conditions

PR – Soles must show no sign of cracks after 1.5 million flexes and must have a minimum puncture resistance of 270 poundsCAN/CSA-Z195

European Class 2 for cut protection

Material used is rated as Class 2 for chainsaw speeds up to 24 meters/sec

Classified by UL®

The UL® mark is visible on any product classified by Underwriters Laboratory (UL) to meet the standards set forth for that product. All SwedePro leg protective garments are tested and classified by UL® according to the ASTM Test Method F1414 in accordance with ASTM Standard F1897

To verify compliance of any UL classified product visit https://productiq.ulprospector.com/en/search

US Forest Service standard 6170-4G

This standard lists what is required for employees of USFS.

Citation: US Forest Service. (1970). National Crosscut and Chainsaw Program PPE. Retrieved from https://www.fs.usda.gov/sites/default/files/2019-12/personal-protective-equipment-required-for-saw-operations-12-30-2019.pdf

Leg Protection

Chaps or cut-resistant pants for chain saw use shall meet the requirements of Forest Service 6170-4 or ASTM F-1897 (current version). Chaps shall overlap boots by at least 2”.

Foot Protection

Cut-resistant or leather, laced 8 inch (204 mm) high boots that provide ankle support and nonskid soles.

Eye Protection

Safety glasses, mesh face shield or “bug-eye” type googles that meet ANSI Z87.1 standard.

Head Protection

Hard hat or cutting helmet meeting ANSI Z89.1.

Hearing protection required for gasoline powered chain saw use.

OSHA Regulation 1910.266

This standard ensures safe working conditions by enforcing the following for employees who run chainsaws.

Citation: Occupational Safety and Health Administration. (1970). Occupational safety and health standards: Logging Operations. (Standard No. 1910.266). Retrieved from https://www.osha.gov/laws-regs/regulations/standardnumber/1910/1910.266

Leg Protection 1910.266(d)(1)(iv)

“The employer shall provide, at no cost to the employee, and assure that each employee who operates a chain saw wears leg protection, constructed with cut-resistant material…”

Foot Protection 1910.266(d)(1)(v)

“The employer shall assure that each employee wears foot protection, such as heavy-duty logging boots that are waterproof or water repellent, cover and support the ankle… constructed with cut-resistant material…”

Head Protection 1910.266(d)(1)(vi)

“The employer shall provide, at no cost to the employee, and assure that each employee who works in an area where there is potential for head injury from falling or flying objects wears head protection…”

Eye Protection 1910.266(d)(1)(vii)(A)

“The employer shall provide, at no cost to the employee, and assure that each employee wears eye protection…where there is potential for eye injury due to falling or flying objects.”

Face Protection 1910.266(d)(1)(vii)(B)

“The employer shall provide, at no cost to the employee, and assure that each employee wears face protection… where there is potential for facial injury such as, but not limited to, operating a chipper. Logger –type mesh screens may be worn by employees performing chain saw operations and yarding.”

First Aid Kit 1910.266(d)(2)(i)

“The employer shall provide first-aid kits at each work site where trees are being cut (e.g., felling, buckling, limbing), at each active landing, and on each employee transport vehicle. The number of first-aid kits and the content of the kit shall reflect the degree of isolation, the number of employees, and the hazards reasonably anticipated at the work site.”

Size and Fit

Chaps

| Your Approximate INSEAM | Your Approximate OUTSEAM | SIZE |

| 29"–30" | 32"–36" | 32 |

| 31"–32" | 36"–40" | 36 |

| 32"–33" | 40"–44" | 40 |

| 33"–34" | 44"–48" | 44 |

Size requirements may vary.

For an accurate fit, measure the outside length of the user’s leg (“outseam”), from the top of the hip down past the top of the work boot. The correct length should cover the top of the boot ending between the 2nd and 3rd lace point. Choose the size above that most closely matches your outseam measurement.

Pants

All Pants come in 4 waist measurements:

- Small 30–32"

- Medium 34–36"

- Large 38–40"

- XLarge 42–44"

And 2 inseams:

- 32"

- 34"

Custom pant sizing is available for an additional fee.

The correct length should cover the top of the boot ending between the 2nd and 3rd lace point.

Boots

- Boots typically run true-to-size in length. All boots come with a red insole for a standard medium width. Two additional insoles are included to help you customize—yellow for a wider, more open fit and blue for a snugger fit.

- Women should order a size and a half smaller.

- Available in sizes 6–14, including half sizes through 12.5.

Wash and Care

All apparel should be washed and dried upon purchase. This product performs better when it is regularly washed and dried. Keeping the fibers clean and dry means that in the case of contact with a saw, they are pulled more easily, jamming the saw, and stopping the rotation. This allows the wearer more time to react. We recommend that all products be washed before first use and cleaned regularly. Use warm water with color safe detergent and machine dry on low. Do not bleach.

If any damage has been made to the product, consider it no longer usable. Any slight pull done to the fibers inside could affect the product’s integrity and ability to perform if needed. The only repairs that can be made are replacing the buckles and zippers.